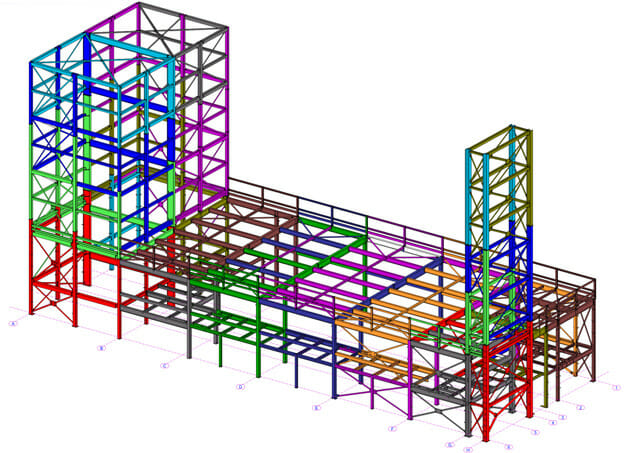

Project: Lee Valley Heat Network

This imposing steel structure will house two enormous cylindrical thermal mass stores, various heating & energy equipment, a new office and meeting room space along with a mezzanine floor above. This futuristic development will serve to significantly improve heat output distribution to homes and businesses within the district of Enfield. In turn this scheme run by Energetik, will greatly reduce the carbon footprint in comparison to conventional heating systems.

Hillcrest worked closely with Vital Energi & the design team throughout the design stage to ensure a fully realised Tekla model was developed. A diverse range of steel section types have been used throughout the design of this galvanised steel frame, from small RSA’s and PFC sections through to the largest available UC profile type (UC356x406.) One of the notable features throughout the frame was the vast amount of stability bracing systems which comprised of either CHS, flats or RSA’s.

In line with the construction sequence, the model was separated into 20 manageable delivery loads for the primary frame. In addition to the primary frame, Hillcrest supplied and installed three staircase units and staircases 2 & 4 included balustrade infill panels. Hillcrest were also responsible for the supply and installation of the metal decking to the mezzanine floor.

Project in numbers; –

- Primary steel frame (excluding stairs) tonnage = 274 tonnes (4,336 parts)

- Stair 1, 2 & 4 combined tonnage = 1 tonnes (795 parts)

- Circa 350m²* of Tata ComFlor 60×1.0-gauge metal decking to mezzanine floor.

- Number of bolts, fixings & H.D bolts = Circa 6000

- Overall length of steel frame = 55 meters

- Overall width of steel frame = 19 meters

- Overall height of steel frame = 30 meters (Flue stack structure)

- Heaviest assembly = 1 meters long UC356x406x467 column weighing 5.1 tonnes.